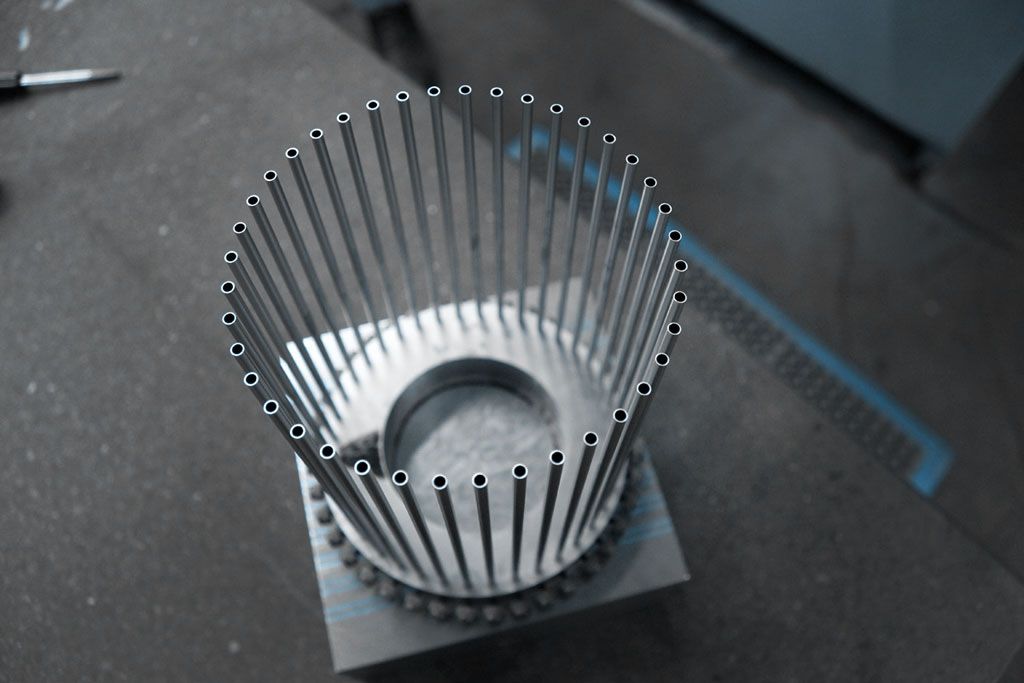

Single face and double face lapping is the process in which one or two surfaces are rubbed together with an abrasive by machine or by hand to achieve a smooth flat surface. To do this a slurry is required which is made by mixing abrasive particles and either a water or oil-based liquid. The slurry is used as the cutting tool between the work pieces and lap plate.

Equipment:

2- 36″

Spitfire Lapping

36″

Lapmaster

24″

Lapmaster

Speedfam 16B-6

Double Face Lapping

Speedfam 9B-5

Double Face Lapping

Request a Quote