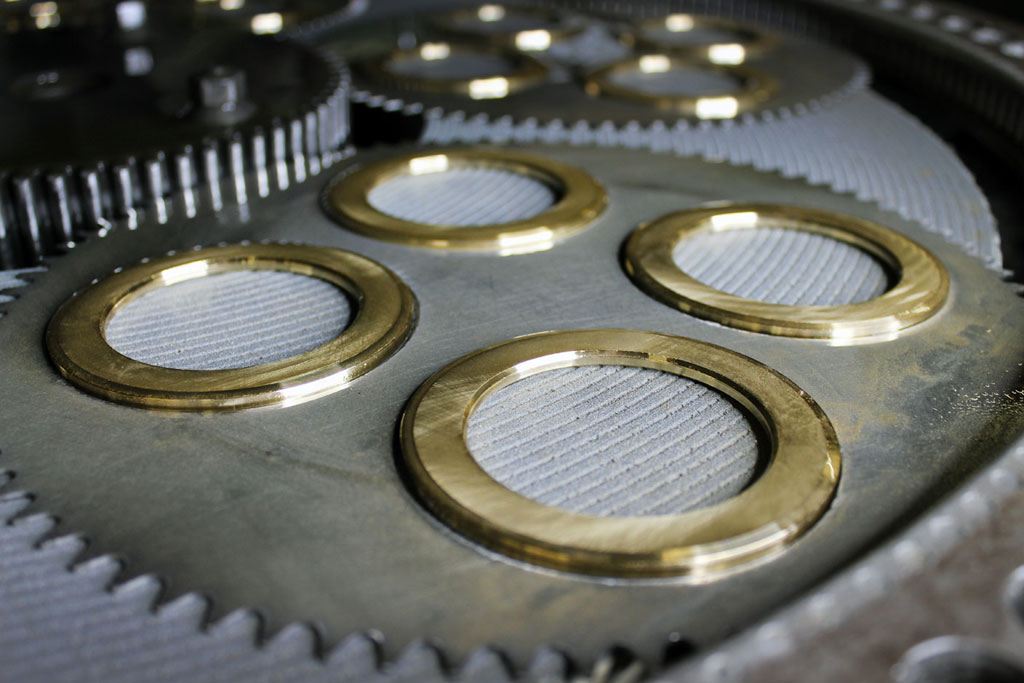

We offer Double Disc grinding which is a double sided “fine grinding” where two opposed grinding wheels are used to remove stock from both faces of a flat part at the same time. Component/parts are held between the two wheels with carrier fixtures throughout the grinding process. Double Disc delivers a high, random-pattern surface finish, typically in the 8 – 16 RMS range on most materials. Flat and parallel results typically within 0.0002.

Equipment:

14- Norton Hyprolap Double Disc Grinders with 3, 4, and 5 rings

Request a Quote